Graphene in fashion technology

Blog by WoW Sao Paulo Ambassador Mariana Queiroz

Since researches and studies have revealed the graphene as the lightest, strongest and thinnest material there is, the race for new discoveries hasn’t stopped. Graphene is derived from graphite and has a thickness of an atom. Because of their incredible properties and the very high potential for innovation, scientists and researchers are increasingly dedicated to new laboratory experiments that seek to understand how much science and experiences with graphene can reach. After all, it’s a superlative and extraordinary material.

Studies and Researches

A scientific article published in the academic magazine ACS Nano, scientists at the University of Manchester report a simple and scalable method of producing durable and washable graphene-based e-textiles with potential to fabricate 150 meters of fabric per minute using the pad-dry technique.

During the study, the researchers demonstrated the possibility of graphene e-textile acting as a monitoring sensor of physical activities. Due to the stable reduced graphene oxide coating (rGO), there’s a change of resistance in the fabric capable of accurately capturing all the user's movements: flexing, unfolding, stretching, relaxation, twisting, and distortion.

By achieving scale production of this material, there will be easy access to graphene technology by fashion designers and industry professionals around the world.

The graphene in fashion and clothing

In this sense, the Textile and Fashion industries are attentive to graphene. But innovation in this market still come slowly. This is mainly due to the high cost of production at scale and the fact that the material is relatively restricted to laboratories. In fact, this is still the general rule, but there are already exceptions that serve as excellent case studies. One example is the Vollebak brand, which launched experimental prototypes of jacket coated with graphene.

Science and Experiments

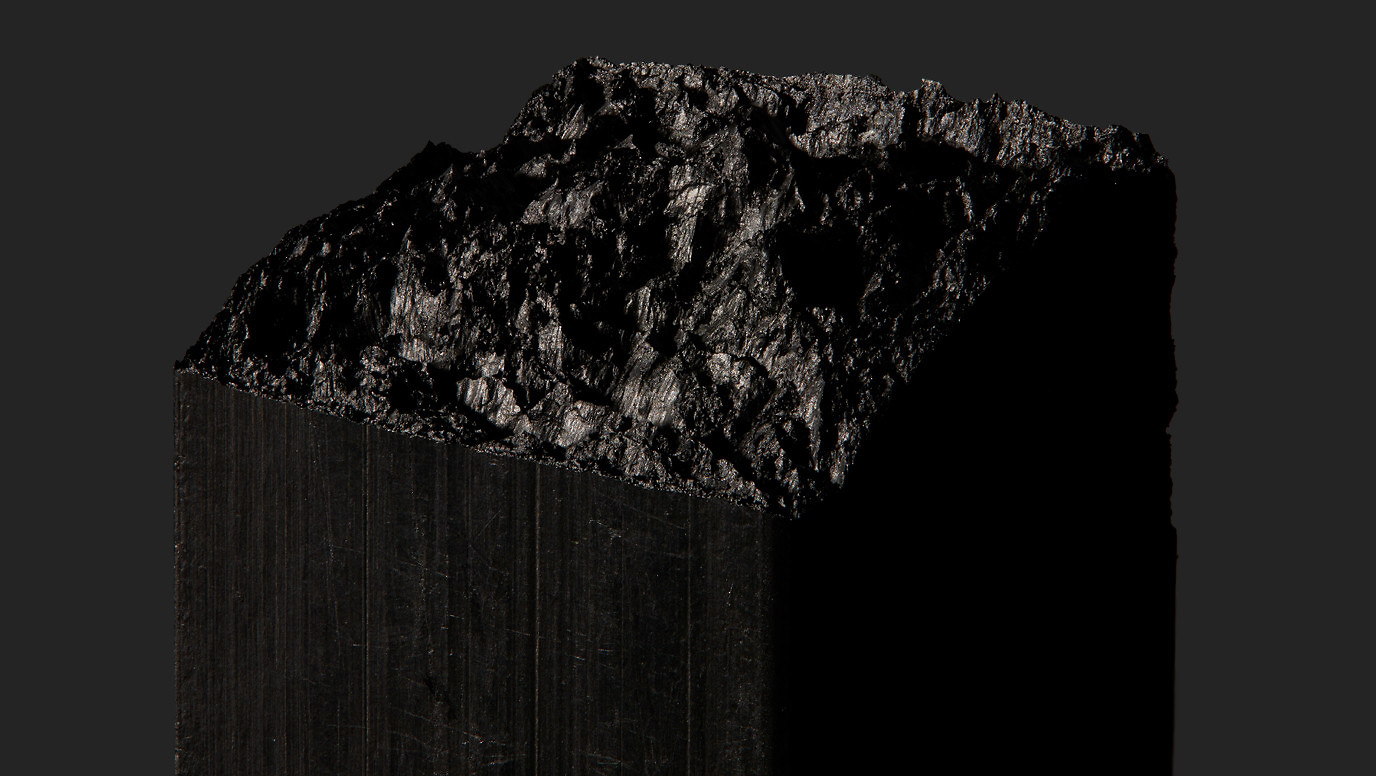

The Graphene Jacket was launched in 2018, a hybrid of scientific experiment and garment. The strategy outlined by the company determined that the first users were a test group. Following the users feedback several improvements are made in the next clothing’s editions. Research and experimentation are the keywords that make it possible to apply graphene to the market.

The Graphene Jacket has been developed to be reversible: that is one side coated with the supermaterial and the other made of super strong stretchable nylon. The graphene side leads very low and safe electricity, besides generating heat and warming the body. Among the features there are many benefits: impermeability and breathability due to narrow atomic bonds (being waterproof and able to evaporate the sweat), prevents the proliferation of bacteria and the smell of sweat, is hypoallergenic and antistatic (non-toxic membrane ) extremely resistant to skinning and perforation, among others. The jacket interacts with the body and the world around you in different ways and according to the variations of the environment.

Nano-platelets

To create the Graphene Jacket it was necessary to transform raw graphite into graphene nano-platelets. Then these nanoparticles, which consist of small graphene cells, are mixed with polyurethane to create an incredibly thin membrane. The bonding of the membrane created with the nylon gives rise to new material. By adding graphene to nylon the chemical and mechanical properties of the fabric change. In this way, nylon becomes capable of conducting heat. This happens without adding 1g of weight to the fabric because graphene is the finest material there is.

Investing in research, experiments, new concepts, production methods, and unpublished materials like these, take time. That's why building the future is a medium to long term project, and the graphene is only at the beginning of this journey.

Graphene Jacket have a long way to go in terms of development and availability, but until then we can rely on our trusty hardshell jackets which you can find in an sports store for waterproof and windproof piece of clothing.

This blog was written by Mariana Queiroz, Women of Wearables Ambassador in São Paulo. She is founder and CEO of Divaholic - a content and consulting platform that can solve big problems based on multi-disciplinary strategy and ideas, for brands who wish to implement wearable technology in their products, making clothing a key tool for user experience design. Over the last three years she has also developed workshops and courses about fashion technology, electronic sewing, 3D printing, biotechnology and sustainability, where more than 200 students have graduated, 95% of them women - who are the majority of their audience. Connect with Mariana via LinkedIn: Mariana Queiroz